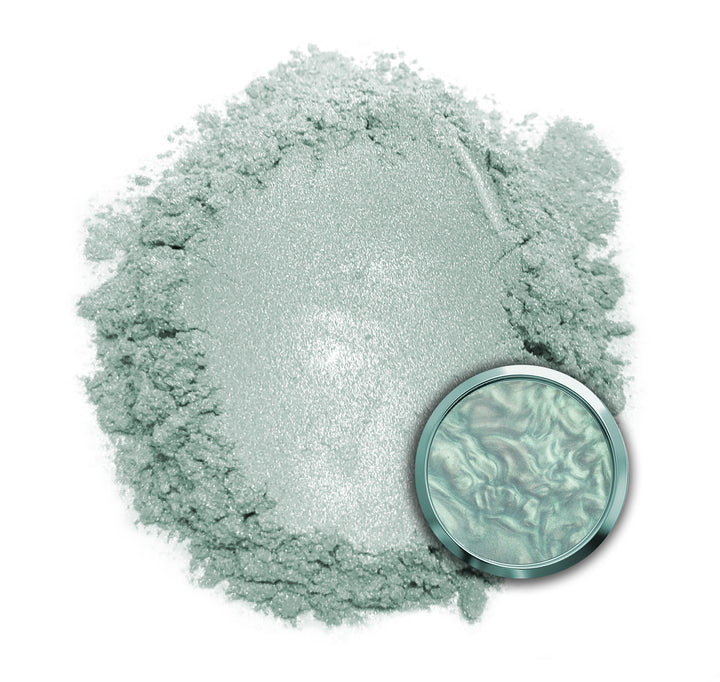

Experience the subtlety of our Gage Green, a light green pigment tinged with grey nuances. This refined shade adds sophistication to every project, capturing attention with its unique blend.

Ideal for acrylic paintings that seek a touch of elegance, or epoxy resin crafts that aim to impress. Let your creativity flourish in slime, bath bombs, jewelry, and beyond. Also perfect for melt & pour, plastics, and candle crafting.

Particle size : 10-60 μm

Ingredients : Synthetic Mica,

Titanium Dioxide, Tin Dioxide, Iron Oxide

Heat Threshold : 212 °F

Product Type : Mica

Vegan : Yes

Soaps : Yes

Epoxy Resin : Yes

Acrylic : Yes

FDA-Permitted for External Use : Yes

FDA-Permitted for Eye Area Use : Yes

FDA-Permitted for General (Including Lips) Use : Yes

FDA-Permitted for Bath Bombs Use : Yes

Epoxy : 2 grams per 8 ounces

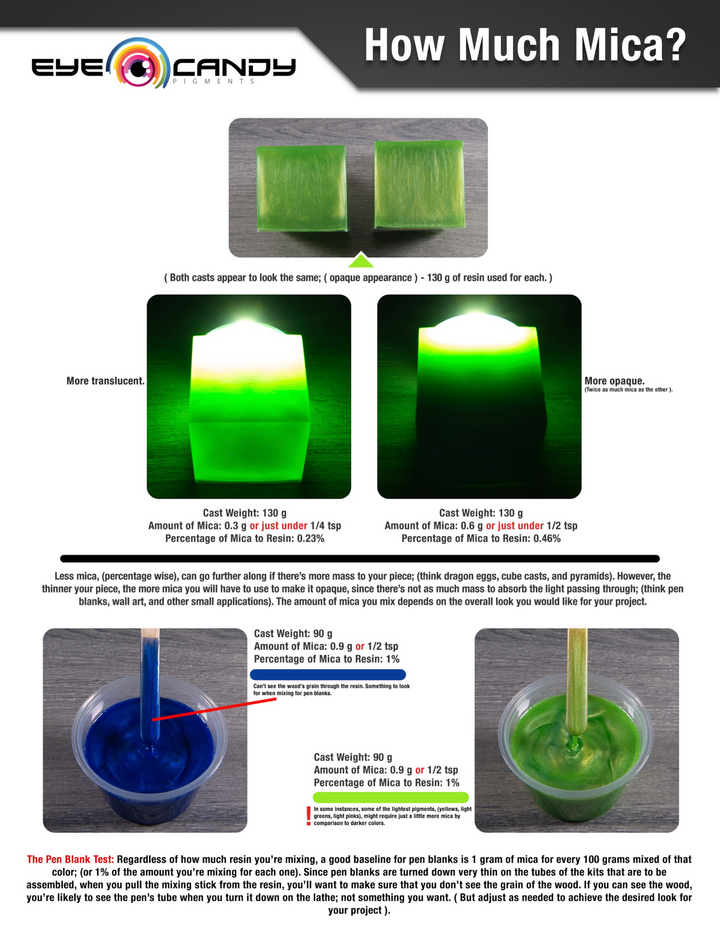

The most common question that we receive is “How much pigment per gallon of epoxy?” This is a very valid question and unfortunately there is no set answer due to the numerous types of applications and variations. This is why we recommend 2 grams per 8 oz and add as desired.

For example: Are you looking for an opaque or transparent look? Lighter colors may take more pigment to achieve the color.

Why micron sizes matter:

PLEASE be aware of the micron sizes of the pigment. The larger the micron, the larger the particle.

Typical pigments average 10-60um.

Be aware that larger micron sized pigments will most likely have a heavier density which will cause the pigment to sink faster in fresh epoxy such as deep pours. For example, our Icicle or 14k Nugget Gold is 200-700um and will most likely sink in fresh epoxy faster. To alleviate sinking either let the epoxy settle up a little bit. Or, come back through your project to “stir” it a little more.

Cold process - 2 tsp per lb of oils

Hot process - ½ tsp lb of MP base

Peelable Automotive Coatings (Plasti Dip, HaloEFX, P1Coatings, Pro Line, Autoflex, Etc.) - 50 Grams Per Gallon

Standard Automotive Clears - 25 Grams Per Gallon

Appliance Paint And Coatings - 25 Grams Per Gallon

Architectural Coatings (Interior And Exterior) - 10-20% By Weight

Wall Paper And Other Architectural Paper Coatings - 1-5% By Weight

Peelable Coatings:

◦ The majority of our pigments can be sprayed through a 1.2 tip

◦ Be aware of the micron size. The larger the particle you may have to go to a larger tip.

◦ The pigments can be mixed with the base color or mixed into the clear and sprayed over the base color.

◦ The base color may impact the overall color of the pigment.

◦ Light colored pigments yellows, pinks, etc., we recommend using a white base or a like colored base.

◦ Dark colored pigments, we recommend using a black or dark colored base

Automotive Paint:

◦ The majority of our pigments can and have been used for automotive.

◦ The majority of our pigments can be sprayed through a 1.2 tip

◦ Three ways to use our pigments for spraying:

◦ Mix directly into the base color to create a unique blend

◦ Mix and spray with your mid clear over the base color

◦ Mix and spray with your top coat. Typically we do not recommend this due to the possibilities of striping. Also, we use the top coat as a UV

protector or possible sanding of the top coat, etc.

Courtesy from our friend Justin Salley.

For more tutorials, visit his Youtube page www.youtube.com/@justinsalleyart/

STEP #1 - MIX YOUR POURING MEDIUM

3 parts Behr8300 Deep Base Interior/Exterior Hi-Gloss Enamel. 1 part JOSONJA Polyurethane Water Based Gloss Varnish. Mix gently folding paint and varnish together until they are completely mixed, Go Slow to reduce mixing bubbles.

STEP #2 - DISPERSING PIGMENTS INTO YOUR MEDIUM

Pour 1/2 to 1 teaspoon of JOSONJA Gloss Varnish into mixing container. Add around a teaspoon of Pigment (I generally add a little more) into your container with the JOSONJA. Mix until all Pigments have dissolved into a liquid making sure to stir any clumps out at this time.

STEP #3 - COMBINING YOUR POURING MEDIUM & DISPERSED PIGMENTS

Add around 3 Tablespoons of Pouring medium into your Dispersed Pigments. Mix thoroughly, being slow and folding rather than whipping, this will minimize the air bubbles.

STEP #4 - WHAT IF?

◦ If your new mixed color seems to thick - Add a small amount of JOSONJA and stir until you reach the desired consistency.

◦ If your new mixed color seems to thin - Add a small amount of Behr8300 (ONLY) and stir until you reach the desired consistency.

Vinyl Wrap And Plastic Films - 5-10% By Weight

Plastic Bottles - 1-2% By Weight

Masterbatch - 10-30% By Weight

Plastic Resins - 0.2-0.5% By Weight

Rubber Polymers And Latex - 5-15% By Weight

Glass - 1-10% By Weight

Candles - 5-10% By Weight

Flexographic Inks (Packing Materials) - 15-25% By Weight

Offset Printing Ink - 5-10% By Weight

Screen Printing And Screen Inks - 10-30% By Weight

Textile Printing And Textile Inks And Pastes - 5-10% By Weight

Gravure Inks - 5-15% By Weight

Lotions - 1-5% By Weight

Lipstick And Pigmented Lipgloss - 5-10% By Weight

Eyeshadow - 15-80% By Weight

Nail Polish - 5-25% By Weight

Shampoo - 0.1-2% By Weight

Our pigments can be used for both Cerakote and KG Gunkote clears. Below are just some references.

◦ 5 grams of pigment per 4oz

◦ Typically recommend a black base. For light colored pigments such as

yellows, pinks, etc. you may want to try a light colored base. ALWAYS test before full application.

◦ 3 coats for full saturation. Some colors may require less.

◦ Stay with pigments with a 10-60um micron size. All particle sizes are listed

on our product pages or you can find them on our Pigment Information List.

◦ Recommend using a .80 spray nozzle. Some use 1.0 for clears.

Light/Translucent Colors: 0.25%–1% pigment per total plastisol weight

Standard Mix: 1%–3% pigment per total plastisol weight

Rich, Opaque Colors: Up to 5%, but too much pigment may affect flow & curing

How This Translates to Grams:

Plastisol Amount | 1% Pigment | 2% Pigment | 3% Pigment | 5% Pigment

100g plastisol | 1g pigment | 2g pigment | 3g pigment | 5g pigment

250g plastisol | 2.5g pigment | 5g pigment | 7.5g pigment | 12.5g pigment

500g plastisol | 5g pigment | 10g pigment | 15g pigment | 25g pigment

1kg (1000g) plastisol | 10g pigment | 20g pigment | 30g pigment | 50g pigment

Which Pigment Size Should You Choose?

5g Pigment – Best for small batch testing (up to ~500g plastisol at 1-2%)

25g Pigment – Great for mid-size projects (~500g-2.5kg plastisol)

50g Pigment – Ideal for larger production runs (~1kg-5kg plastisol)

We recommend starting with a lower percentage (1-2%) and gradually adjusting based on the intensity you're looking for. Metallic and interference pigments may require extra mixing for even dispersion.

Materials Needed:

Mica Pigments: Choose the colors you want to use.

Lacquer Thinner: A solvent that helps to dissolve the pigments and facilitate the dyeing process.

Mixing Container: Use a glass or metal container that is resistant to solvents.

Stirring Stick: A metal or plastic stick to mix the pigments with the lacquer thinner.

Protective Gear: Gloves, goggles, and a mask to protect yourself from fumes and spills.

Brush or Cloth: For applying the mixture to the wood.

Sealer: To protect the dyed wood once it’s dry.

Preparation:

Ensure you are working in a well-ventilated area or outdoors.

Wear protective gear to avoid inhaling fumes or contact with skin.

Mixing:

Pour a small amount of lacquer thinner into your mixing container.

Gradually add mica pigments to the lacquer thinner. Start with a small amount and add more as needed to achieve the desired color intensity.

Stir the mixture thoroughly until the pigments are fully dissolved and evenly dispersed. This may take a few minutes to ensure there are no clumps.

Testing:

Before applying to your final piece, test the mixture on a scrap piece of wood. This allows you to see the color and make any necessary adjustments.

If the color is too light, add more pigment. If it’s too dark, dilute with additional lacquer thinner.

Application:

Apply the mixture to the wood using a brush or cloth. Work in long, even strokes to ensure consistent coverage.

Allow the first coat to dry completely before applying additional coats if needed. This usually takes about 15-30 minutes, but check the product instructions for specific drying times.

Finishing:

Once the desired color is achieved and the wood is fully dry, apply a sealer to protect the finish. This can be a clear lacquer, polyurethane, or another wood sealer compatible with your project.

Ventilation: Always work in a well-ventilated area to avoid inhaling fumes.

Small Batches: Mix pigments in small batches to avoid waste and ensure freshness.

Consistent Mixing: Keep the mixture well-stirred during application to maintain consistent color.

Safety: Follow all safety instructions for handling lacquer thinner and pigments. Dispose of any rags or brushes used safely, as they can be flammable.

To request a SDS, please email us at jeff@eyecandycustomz.com

First time using Gage Green and I purchased it for a client to match their appliance colors. I love the mixture of greens it has while keeping it stirred as the epoxy cures! I've never once been disappointed by Eye Candy pigments and they are by far my favorite pigment to use!

Nothing, beautiful.

Love the color blend in this and all of their mica powders

Eye candy pigment powder has been an amazing staple in my business. It is so reliable each time I re purchase a color. I can depend on it being exactly the same.

I am a resin artist and have quite the collection of various pigments, paints and ink. I tend to gravitate towards mica pigment the most and for my needs, this doesn't disappoint. This particular color is two-toned and looks great when the mica is moved around. It shifts from a medium-light gray to seafoam. I'd share a picture, but a photographer I am not and I wouldn't do the color justice.